NOW LIVE! Click here to visit our eBay store

Laminate Doorsets

Hard-wearing and heavy-duty, ideal for commercial environments

Interspec Doorsets offer a wide range of coloured and wood replica high-pressure laminate HPL facings from the Formica® Laminate Collection.

Laminate doors are favoured in many commercial applications as they are typically known for being exceptionally hard-wearing, heavy-duty doors.

Wood Replica Range

Doors are faced with an HPL woodgrain effect and are hardwood lipped on four edges, or alternatively can be PVC edged.

Plain Colour Range

Doors are faced with laminate from our plain colour ranges varying from bright, bold solid colours to subtle tones and are supplied hardwood lipped on four edges, or alternatively can be PVC edged.

For more details, please visit our Brochures page to download our Doorsets brochure and Formica® Laminate Collection brochure.

- Doorset Benefits

- Performance

- Vision Panels

- Technical

- Fitting Instructions

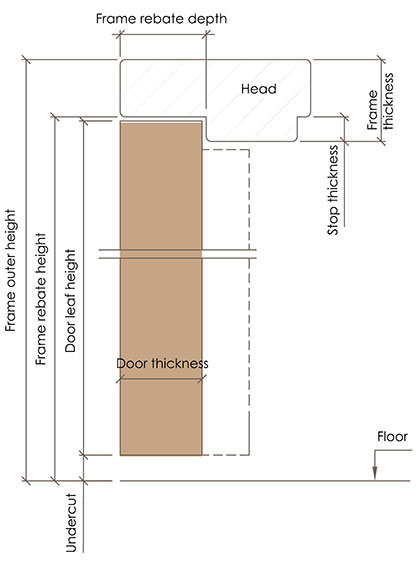

At Lloyd Worrall we have identified the need for a full high performance doorset inclusive of ironmongery and access control resulting in the following benefits to the customer:

- All doors are DD171 severe duty rated as standard.

- Frame sections are manufactured using engineered softwood for stability.

- Delivery performance record is 99.1% on time, in full.

- Full doorset, ironmongery and access control service, incorporating an experienced fully qualified team, dealing with specification, estimating, scheduling and project management.

- Co-ordinated products ensuring complete compatibility resulting in the compliance with fire, smoke and acoustic regulations for all building and project types, reducing the risk of on-site failures due to uncoordinated components.

- Factory preparation and installation of non-projecting ironmongery, including hinges, lock case, lock keep and flush bolts, ensuring accuracy is maintained under manufacturing systems control.

- Reduced site installation costs, snagging issues and on-site waste. Doorsets reduce the potential for on-site health and safety issues concerning assembly and door ironmongery preparation.

- Multi-supplier provision of doorset components can be costly, time consuming and inefficient. The Interspec Doorset provides manufacturing accuracy, quality and performance. This integrated package offers significant cost benefits when compared with traditional installation costs.

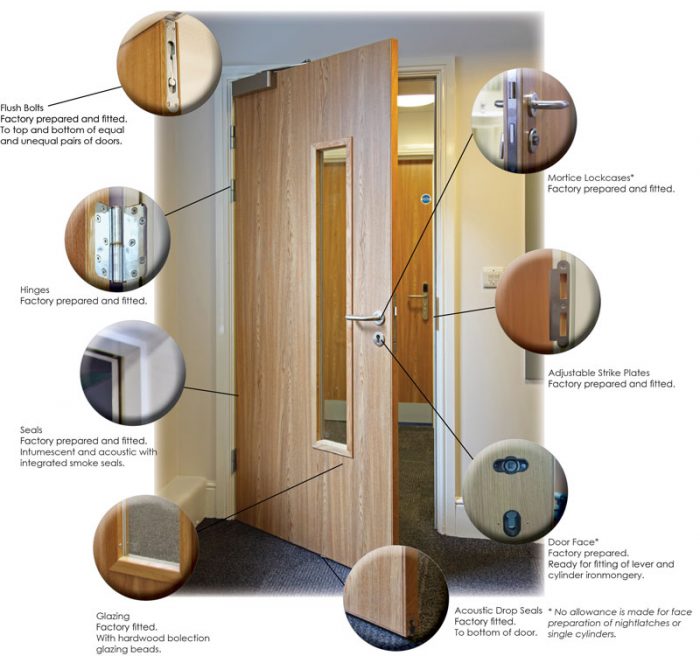

Door Core: Solid Core Flaxboard Core

Interspec Doorsets are manufactured from a flaxboard central core with timber stiles and rails to all four edges. They are sub-faced and edged and then faced (veneer or laminate).

The timber stile and rail system ensures complete compatibility for a severe duty performance and provides a secure and solid fixing for critical items of ironmongery.

Interspec Doorset Performance

| Interspec Doorset Performance | Fire | Smoke | Acoustic Level | Surface Performance | Mechanical Strength | Intumescent Seals | Smoke Seals |

| Timber Doorset-Veneered | Yes | Yes | 30dBRw to 43dBRw | Medium Duty | Severe Duty | Yes | Yes |

| Timber Doorset-Laminate | Yes | Yes | 30dBRw to 43dBRw | Heavy Duty | Severe Duty | Yes | Yes |

| Timber Doorset-Fully Painted | Yes | Yes | 30dBRw to 43dBRw | Heavy Duty | Severe Duty | Yes | Yes |

| Standards | BS476 pt22 | BS476 pt 31.1 | BSEN ISO 140-3 BSEN ISO 717/1 | BS3962 EN438 | BSDD171 | BS476 pt22 | BS476 pt 31.1 |

Fire

FD30, FD60, FD90 and FD120 certified fire doors.

Smoke Control

Fire doors are also certified for smoke control (FD30S, FD60S, FD90S, FD120S).

Durability

A range of doorsets have been tested in accordance with DD171 and EN1192 resulting in a severe duty rating.

These specify the performance requirements for hinged and pivoted doors and classifies them by strength and durability based on four categories:

Light: Private dwellings.

Medium: Offices and dwelling with higher risk of damage.

Heavy: Hospitals and public buildings.

Severe: Educational establishments.

Acoustic rated doorsets require accurate sealing and installation to achieve the desired performance.

Sound Reduction – Frequency

The number of vibrations per second expressed in Hertz:

- Low frequency (40Hz to 400Hz)

- Medium frequency (400 to 1600Hz)

- High frequency (1600Hz to 20000Hz)

Sound Pressure Level

The measurement of sound level in decibels (dB) with the sound reduction index (Rw).

Sound Reduction

The weighted sound reduction index is measured in accordance with:

- EN ISO 140.3 (measurement of sound insulation in buildings)

- EN ISO 717.1 (classification of sound insulation in buildings)

Sound Insulation

The Rw ratings are for the doorset only. Manufacturers sometimes provide sound insulation data as a combined rating for the wall and doorset. The actual Rw rating of the doorset should be calculated using a percentage of the wall area it occupies. The wall rating is generally higher than the required doorset. Please refer to the table below.

| Type of space used by students | Minimum Rw (dB) | Minimum Rw (dB) | Product |

| Wall including any glazing | Doorset | ||

| All spaces except music room | 40 | 30 | Rw 33 dB |

| Music Rooms | 45 | 35 | Rw 38 dB |

Threshold and Drop Seals

Threshold seals are necessary in order to maintain the required acoustic performance level.

A drop-down seal or wiper seals with a rubber threshold will achieve the requirement at floor level. Any acoustic performance is fully dependant on the elimination of sound penetration, the area between the wall and the back of the door frame must be fully sealed.

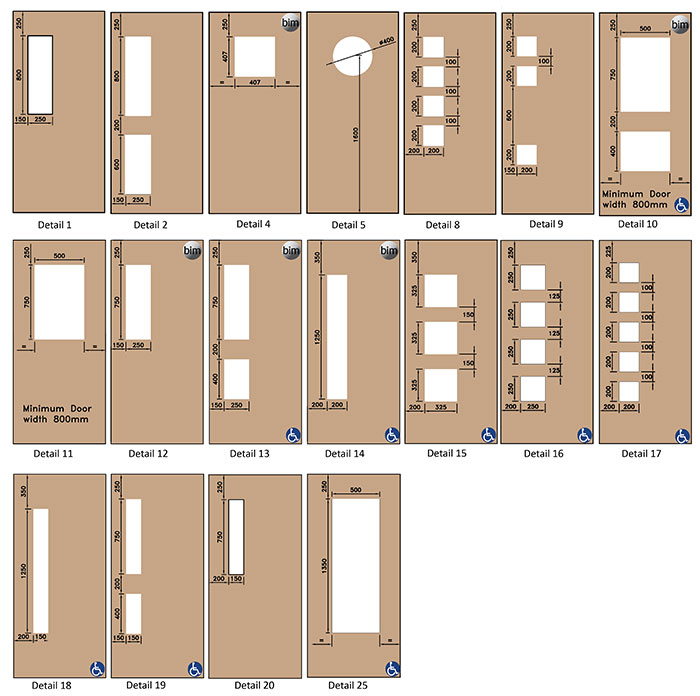

Interspec Doorsets offers a range of aperture styles designed to suit many applications. Additional options are available upon request. Cut outs for classified products are subject to maximum allowances in fire/sound certification.

Factory Glazing

As standard, doors are delivered glazed.

![]() = Equality Act compliant vision panels.

= Equality Act compliant vision panels.

![]() = Interspec Doorset bim object available.

= Interspec Doorset bim object available.

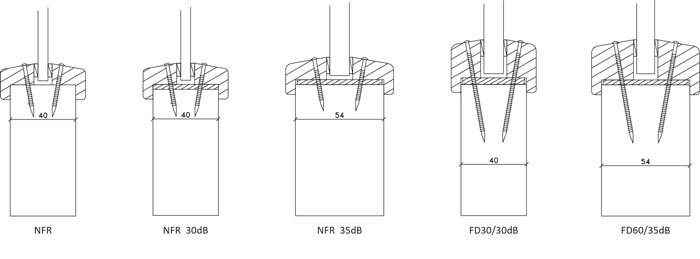

Glazing Bead Detail

Glazing bead is screw fixed as standard.

Glass thickness ranges from 6mm to 17mm dependant on performance.

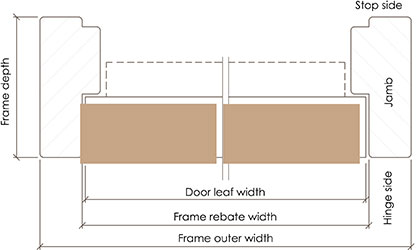

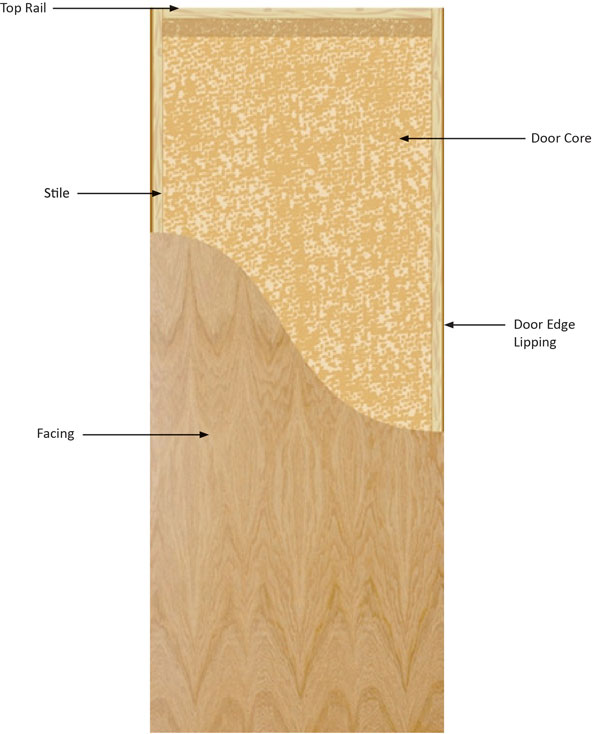

Configurations and Sizes

The Interspec Doorset has an extensive range of configurations and styles. Regulatory compliance fit for purpose and safety are integral to the design whilst maintaining the desired aesthetic appearance and performance.

The table below outlines the standard configurations together with the basic dimensional principals of our doorset packages.

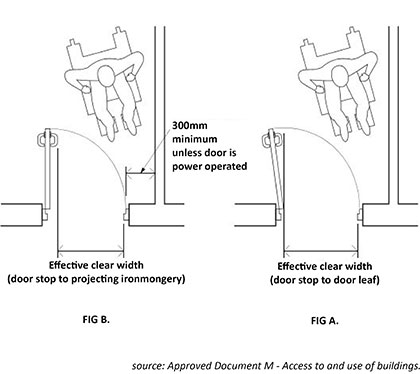

| Structural Opening | Door Type | Frame Size | Rating | Door Thickness | Door Leaf Size | Clear Opening Width Fig A* | Clear Width Opening Fig B* |

| 900 x 2100mm | Single | 886 x 2089 | NFR/FD30 | 40 | 825 X 2054 | 765mm | 701mm |

| 1000 x 2100mm | Single | 986 x 2089 | NFR/FD30 | 40 | 925 X 2054 | 865mm | 801mm |

| 1100 x 2100mm | Single | 1086 x 2089 | NFR/FD30 | 40 | 1025 X 2054 | 965mm | 901mm |

| 900 x 2100mm | Single | 886 x 2089 | FD60 | 54 | 825 X 2054 | 751mm | 687mm |

| 1000 x 2100mm | Single | 986 x 2089 | FD60 | 54 | 925 X 2054 | 851mm | 787mm |

| 1100 x 2100mm | Single | 1086×2089 | FD60 | 54 | 1025X2054 | 951mm | 887mm |

| 1400 x 2100mm | Leaf & Half | 1386 x 2089 | NFR/FD30 | 40 | 925/396 X 2054 | 878mm | 814mm |

| 1500 x 2100mm | Leaf & Half | 1486 x 2089 | NFR/FD30 | 40 | 925/496/2054 | 878mm | 814mm |

| 1400 x 2100mm | Leaf & Half | 1386 x 2089 | FD60 | 54 | 925/396/2054 | 864mm | 800mm |

| 1500 x 2100mm | Leaf & Half | 1486×2089 | FD60 | 54 | 925/496/2054 | 864mm | 800mm |

| 1800x2100mm | Double | 1786 x 2089 | NFR/FD30 | 40 | 860/860X2054 | 814mm | 750mm |

| 1900 x 2100mm | Double | 1886×2089 | NFR/FD30 | 40 | 910/910X2054 | 864mm | 800mm |

| 1800 x 2100mm | Double | 1786 x 2089 | FD60 | 54 | 860/860X2054 | 800mm | 736mm |

| 1900 x 2100mm | Double | 1886×2089 | FD60 | 54 | 910/910X2054 | 850mm | 786mm |

*please note a standard handle projection of 64mm is used in these calculations. For unequal pairs, the clear opening is calculated on the basis that the secondary leaf is kept locked.

Building Tolerance

All prepared openings should be equal in wall thickness at all points and plumb and square tolerances of +10/-0 in the width and +5/-0 in the height.

Dimensional Tolerances

All manufacturing processes require certain tolerances when working with natural materials that tend to move with climatic conditions. Lloyd Worrall work within the tolerances of BS4787 Pt.1 for internal and external wood doorsets, door leaves and frames.

| Variation Tolerance (mm) | Tolerance (mm) |

| in width & height of frame | +2.0 / -2.0 |

| in width & height of door leaf | +1.5 / -1.5 |

| in thickness of door leaf | +1.0 / -1.0 |

| bow in the length of door leaf | 4.0 |

| cup in width of door leaf | 2.0 |

| twist across door leaf | 6.0 |

| deviation in squareness per 500mm | 1.5 |

| deviation in load surface flatness per 200mm | 0.5 |

Step-by-Step Doorset Installation Video

We’ve created a toolbox talk installation video to show how to install our Interspec Doorsets.